Understanding Industrial Blower Parts: A Comprehensive Guide

The Importance of Industrial Blower Parts in Various Industries

Industrial blowers play a crucial role in a multitude of sectors, including construction, manufacturing, and hospitality. Understanding the components that make up these blowers is essential for optimal performance and longevity.

1. What are Industrial Blow Dry/Out Services?

The term Blow Dry/Out Services refers to the process of using industrial blowers in various settings to effectively dry or remove debris, moisture, and air pollutants. These services are essential for maintaining clean work environments, ensuring the longevity of machinery, and enhancing overall operational efficiency.

1.1 Key Uses of Blow Dry/Out Services

- Construction Sites: To clear debris and dust for safer work conditions.

- Manufacturing Facilities: For drying processes and ventilation.

- Commercial Spaces: Keeping areas clean and reducing moisture accumulation.

2. Types of Industrial Blower Parts

An industrial blower consists of several significant components, each serving a specific purpose. Below is a detailed look at the common industrial blower parts:

2.1 Blower Housing

The blower housing is the outer casing that protects the internal components. It ensures that air is directed appropriately and minimizes noise levels. High-quality materials are often used to withstand harsh environments.

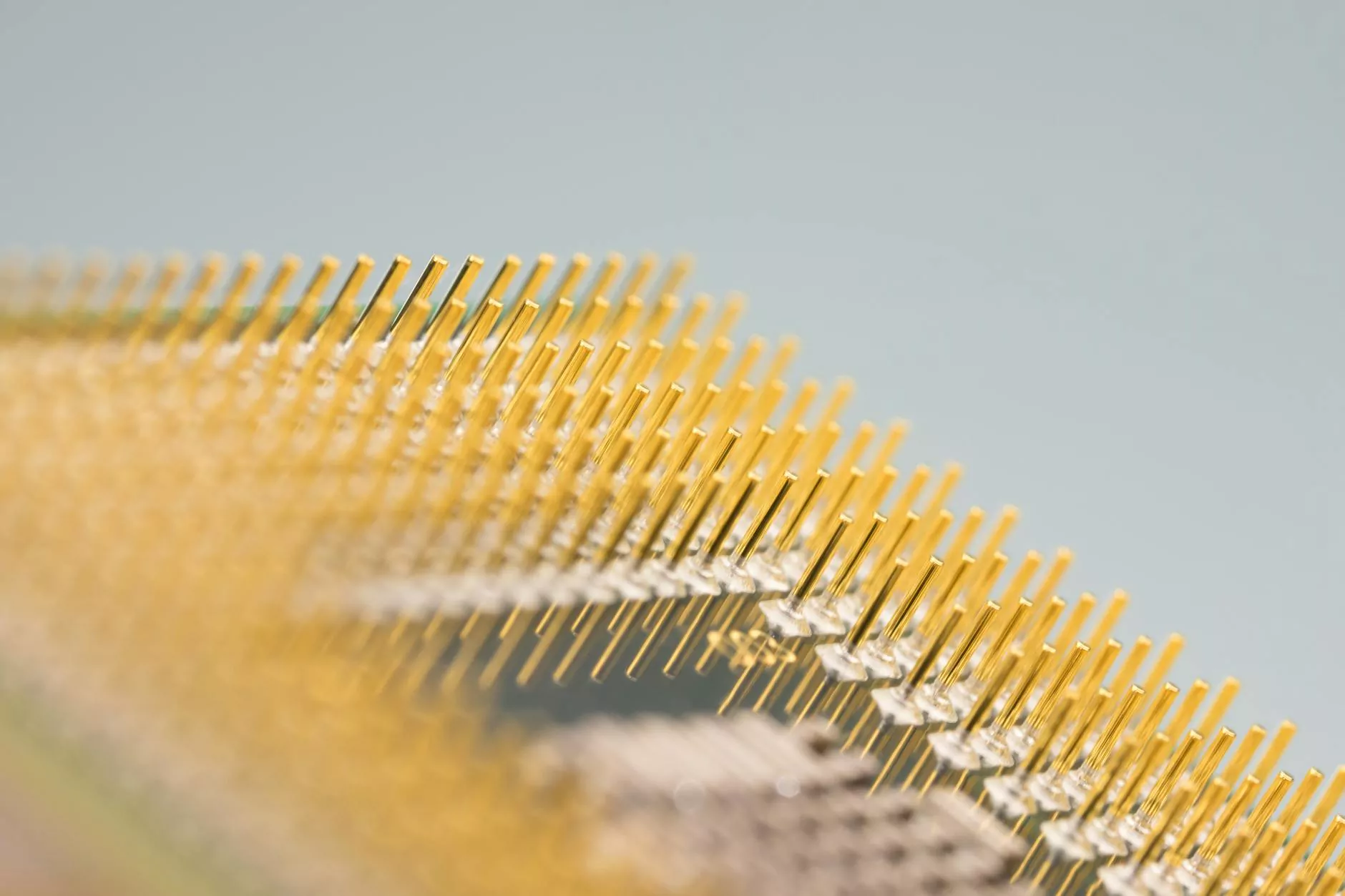

2.2 Impeller

The impeller is the heart of the industrial blower, responsible for moving air. It consists of blades that rotate at high speeds to create airflow. The efficiency and design of the impeller directly affect the performance of the blower.

2.3 Motor

The motor drives the impeller, providing the necessary power to generate airflow. Different types and sizes of motors can be utilized, depending on the application and required airflow capacity.

2.4 Bearings

Bearings support the rotating impeller and ensure smooth operation. They help in reducing friction, thereby enhancing energy efficiency and prolonging the blower's lifespan.

2.5 Inlet/Outlet Ducts

The inlet and outlet ducts serve as pathways for air intake and exhaust. Their design is crucial for optimizing airflow and maintaining pressure within the system.

3. Key Benefits of Using Quality Industrial Blower Parts

Investing in high-quality industrial blower parts can lead to numerous benefits, ensuring that your equipment operates at peak performance:

- Enhanced Efficiency: Quality parts improve airflow and reduce energy consumption.

- Reduced Downtime: Reliable components minimize the risk of breakdowns.

- Cost-Effective Maintenance: Well-manufactured parts typically require less frequent replacements.

4. Maintenance Tips for Industrial Blower Parts

Proper maintenance of your industrial blower parts is essential to ensure their longevity and optimal performance. Below are some effective maintenance tips:

4.1 Regular Cleaning

Dust and debris can accumulate on blower parts, hindering performance. Regular cleaning helps maintain airflow and prevents mechanical issues.

4.2 Inspection of Components

Routine inspections of industrial blower parts can identify signs of wear and tear early, allowing for timely replacements before a failure occurs.

4.3 Lubrication of Moving Parts

Ensure that all moving parts, particularly bearings and motors, are well-lubricated to reduce friction and heat build-up.

4.4 Checking for Air Leaks

Air leaks can severely reduce the efficiency of your blower. Regularly check all connections and ducts for signs of leaks and repair them immediately.

5. Common Challenges in Managing Industrial Blower Parts

Even with diligent maintenance, challenges can arise when managing industrial blower parts. Understanding these challenges can help in mitigating issues:

5.1 Component Wear and Tear

Over time, components like impellers and bearings may wear out due to constant use. Choosing durable materials can help prolong their lifespan.

5.2 Corrosion and Rust

Exposure to moisture can lead to corrosion in metal parts. Using corrosion-resistant materials and regularly inspecting parts can help combat this issue.

5.3 Electrical Failures

Electrical failures can arise from overloading motors or poor wiring. Ensure that electrical components are upgraded to match the demands of your application.

6. Choosing the Right Industrial Blower Parts

Selecting the right parts for your industrial blower is crucial for its performance and efficiency. Here are some tips on making informed choices:

6.1 Compatibility

Ensure that the parts you choose are compatible with your specific blower model. Always refer to manufacturer specifications for optimal results.

6.2 Quality Assurance

Select parts from reputable suppliers that provide quality assurance and warranties. Investing in high-quality parts can save costs in the long run.

6.3 Technical Support

Choose suppliers who offer technical support and resources to assist you in making informed decisions about maintenance and upgrades.

7. Conclusion: The Future of Industrial Blower Part Technology

The technology surrounding industrial blower parts continues to evolve, with advancements aimed at enhancing efficiency and sustainability. As industries grow, the demand for more efficient and eco-friendly blowers will increase, pushing manufacturers to innovate further.

Embracing these advancements can lead to better operational efficiency, reduced costs, and a more sustainable environmental footprint.

For businesses looking to invest in solid, reliable industrial blower parts, TMM with the domain tmm.com.tr provides a range of high-quality solutions tailored to meet the diverse needs of various industries.

With a commitment to excellence, you can ensure that your blowers function well, enhancing your overall production capabilities.