Global Vacuum Presses: The Pinnacle of Efficiency and Performance

In the rapidly advancing world of manufacturing and material processing, global vacuum presses have emerged as essential tools for achieving high-quality results with minimal waste. These advanced machines are pivotal in various applications, ensuring that businesses maintain competitive edges, reduce costs, and enhance product quality.

Understanding Vacuum Press Technology

Vacuum presses utilize the principles of vacuum suction to apply consistent and even pressure across materials. This technology is particularly beneficial for industries such as woodworking, composite manufacturing, and even food processing. By employing global vacuum presses, manufacturers can ensure uniformity in production, which translates to superior final products.

The Mechanism of Vacuum Presses

At their core, vacuum presses operate by removing air from a sealed chamber, allowing atmospheric pressure to compress materials tightly against molds or other surfaces. This process not only improves adhesion between layers but also eliminates air pockets that could compromise the structural integrity of the final product. Here’s a quick overview of how they function:

- Sealing: The materials are placed within a vacuum chamber that is sealed to prevent air from entering.

- Evacuation: A vacuum pump removes the air, creating a low-pressure environment.

- Pressure Application: As air is evacuated, the surrounding atmospheric pressure compresses the materials, ensuring a tight fit.

- Heating (if applicable): Some processes also involve heating to enhance material properties.

Key Components of Global Vacuum Presses

To fully harness the capabilities of global vacuum presses, understanding the various components involved is crucial. Different types of membranes and vacuum system parts play significant roles in the functionality and efficiency of these machines.

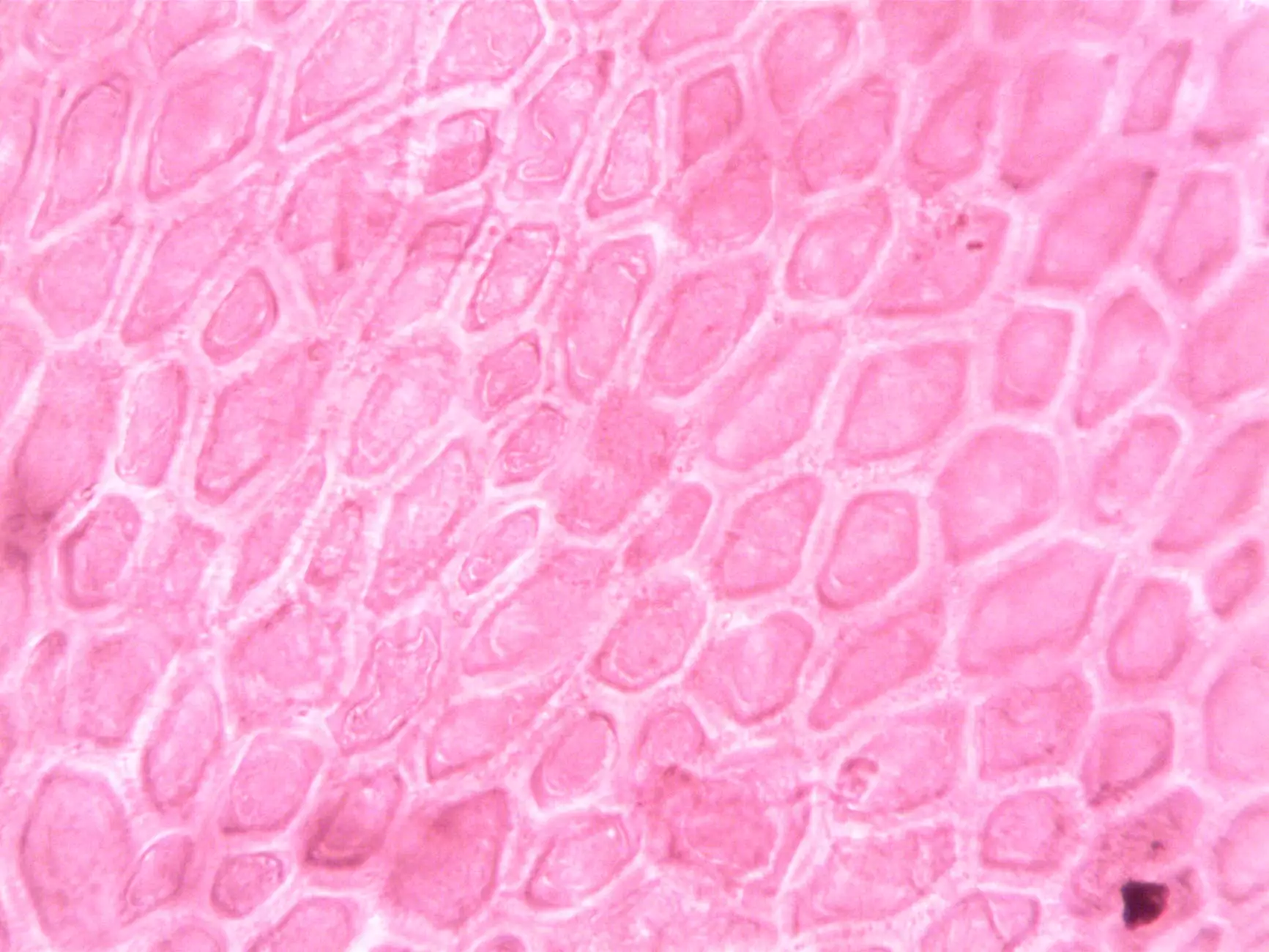

Membranes: The Heart of Vacuum Pressing

Membranes are fundamental to the operation of vacuum presses. They act as a flexible barrier, conforming to the shape of the material being processed. The choice of membrane can dramatically affect the outcome of the press. Below are the common types:

- Silicone Membranes: Known for their high-temperature resistance and flexibility, silicone membranes are ideal for a variety of applications, especially when dealing with composite materials.

- Rubber Membranes: These are robust and provide excellent compressibility, making them suitable for wood and other softer materials.

- Natural Rubber Membranes: Although similar to synthetic rubber, natural rubber offers superior stretchability and is often favored for applications requiring a tight fit.

Vacuum System Parts: Essential for Performance

A complete vacuum system is comprised of many parts that work in unison. Key components include:

- Vacuum Pumps: The lifeblood of any vacuum system, determining the efficiency and speed of the vacuum operation.

- Control Systems: These allow users to monitor and manage the vacuum levels and process parameters effectively.

- Chambers and Hoses: Constructed from durable materials to withstand the rigors of the vacuum environment.

The Advantages of Using Global Vacuum Presses

Integrating global vacuum presses into business operations provides numerous advantages that enhance productivity and product quality:

- Improved Product Quality: The application of uniform pressure ensures a defect-free finish.

- Increased Efficiency: Quick operation cycles reduce manufacturing times significantly.

- Minimized Material Waste: Vacuum technology reduces the amount of excess adhesive or resin used.

- Versatility: Suitable for a range of materials, including wood, composites, and plastics.

Considerations for Buying Global Vacuum Presses

When looking to invest in global vacuum presses, several critical factors need careful consideration:

Material Compatibility

Ensure the vacuum press is compatible with the materials you intend to work with. Different materials may require specific types of membranes and pressure settings.

Size and Capacity

Assess the size of the projects your business handles to choose an appropriately sized vacuum press that meets your production needs.

Features and Technology

Look for modern features like digital control systems, automatic pressure regulation, and efficient vacuum pumps, which contribute to the overall ease of use and performance.

Maintenance Tips for Global Vacuum Presses

To ensure longevity and optimal performance, regular maintenance of global vacuum presses is essential. Here are some best practices:

- Regular Inspections: Check for any wear and tear on membranes and components.

- Cleaning: Keep vacuum chambers and hoses free from debris.

- Lubrication: Regularly lubricate moving parts, as per manufacturer guidelines.

- Calibration: Periodically calibrate control systems to maintain accurate pressure levels.

Case Studies: Success with Global Vacuum Presses

Many companies have successfully leveraged the capabilities of global vacuum presses to enhance their manufacturing processes. Here are two examples:

Case Study 1: A Woodworking Firm

A mid-sized woodworking firm integrated a vacuum press into their production line to laminate surfaces with precision. As a result, they reported a 30% increase in efficiency and a significant reduction in defective products.

Case Study 2: A Composite Manufacturing Company

A company specializing in composite materials gained an edge in the market after adopting advanced vacuum pressing technology, allowing them to produce lighter and stronger components, which are in high demand in the aerospace industry.

Conclusion: Elevating Your Business with Global Vacuum Presses

Adopting global vacuum presses can revolutionize your business operations, improve efficiency, and deliver higher product quality. With the right fittings, components, and maintenance, these sophisticated machines can provide a significant return on investment. Explore options from vacuum-presses.com to find the vacuum press that suits your unique needs and take the first step toward transforming your production capabilities.