Leading Metal Fabricators Specializing in Injection Molding Manufacture at DeepMould.net

In today's highly competitive industrial landscape, metal fabricators play a pivotal role in transforming raw materials into high-precision components that power countless sectors—from automotive and aerospace to consumer electronics and medical devices. At DeepMould.net, we pride ourselves on being at the forefront of this dynamic industry, specializing in injection molding manufacture to meet the rigorous demands of modern manufacturing.

Understanding the Critical Role of Metal Fabrication in Modern Industry

Metal fabrication encompasses a broad array of processes that transform raw metallic materials into usable components and assemblies. From cutting and welding to bending and assembling, these techniques are vital in creating parts that are not only functional but also durable and aesthetically appealing. Among the various methods, injection molding manufacture stands out as a precision-driven technique that allows for the mass production of complex metallic parts with tight tolerances.

The Art and Science of Injection Molding in Metal Fabrication

Injection molding manufacture is a sophisticated process that involves injecting molten metal into carefully designed molds to produce parts with intricate geometries and high dimensional accuracy. Originally developed for plastics, the adaptation of injection molding to metals—often referred to as metal injection molding (MIM)—has revolutionized manufacturing by enabling the large-scale production of small, complex metal components.

Why Choose Injection Molding for Metal Fabrication?

- High Precision: Achieving tight tolerances suited for intricate designs and complex geometries.

- Cost Efficiency: Economies of scale provide reduced unit costs for high-volume production runs.

- Material Versatility: Compatible with a wide range of alloys including stainless steel, titanium, and nickel-based superalloys.

- Complex Design Capabilities: Enables manufacturing of parts with complex internal channels and detailed features that are difficult to produce via traditional methods.

DeepMould.net’s Commitment to Excellence in Metal Fabrication

DeepMould.net has established itself as a leader in metal fabrication by investing heavily in cutting-edge technologies, state-of-the-art equipment, and highly skilled professionals. Our specialization in injection molding manufacture ensures that our clients receive products that meet the highest standards of quality, precision, and consistency.

Advanced Technologies That Drive Our Success

Our facilities are equipped with the latest metal injection molding (MIM) machinery, including high-precision presses, laser sensors for quality inspection, and sophisticated CAD/CAM systems for designing and manufacturing molds. These technological capabilities allow us to produce parts with complexities that far surpass traditional fabrication techniques.

Dedicated Quality Control and Assurance

Quality is the cornerstone of our services. Our comprehensive quality management systems ensure that each product undergoes rigorous inspections at various stages of manufacturing. We utilize non-destructive testing, coordinate measuring machines (CMM), and metallurgical analysis to verify material integrity and dimensional accuracy, exceeding industry standards.

The Benefits of Partnering with DeepMould.net in Metal Fabrication

Choosing DeepMould.net as your metal fabrication partner offers numerous advantages, particularly when it comes to injection molding manufacture.

- Customized Solutions: We tailor our manufacturing processes to meet the specific needs of each project, ensuring optimal results.

- Rapid Prototyping: Accelerate your product development cycle with our quick-turnaround prototype services.

- Large-Scale Production: Our efficient processes support mass production without compromising quality.

- Material Expertise: Extensive knowledge of various metal alloys ensures that your parts perform under demanding conditions.

- End-to-End Service: From initial design consultation to final assembly, we provide comprehensive support at every stage.

Industries That Benefit from Advanced Metal Fabrication & Injection Molding Manufacturing

Our expertise in injection molding manufacture serves a diverse range of industries, each requiring precision engineering and high-quality components. These include:

- Automotive Industry: Producing durable, lightweight, and complex metal parts like gear components, valve bodies, and structural elements.

- Aerospace: Fabricating critical components with high tolerance and reliability standards.

- Medical Devices: Manufacturing biocompatible, precision-engineered parts such as surgical instruments and implant components.

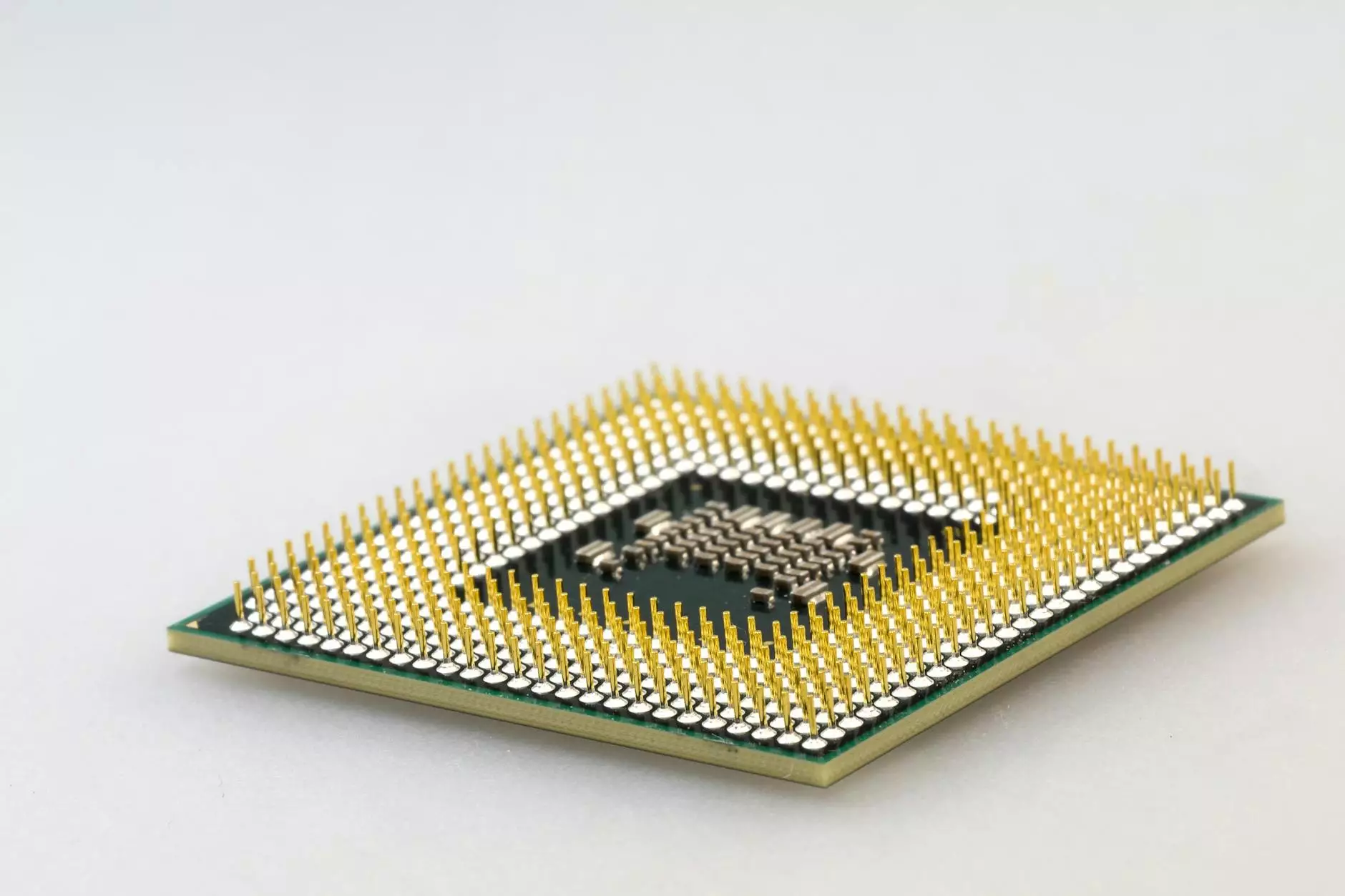

- Electronics: Creating intricate metal parts for connectors, enclosures, and heat sinks.

- Industrial Machinery: Building robust components that endure harsh operating environments.

Innovations in Metal Injection Molding at DeepMould.net

Innovation is at the heart of our operations. Our research and development team continually explores new materials, improved mold designs, and advanced manufacturing techniques. Recent innovations include:

- Development of High-Performance Alloys: Expanding our material portfolio to include advanced superalloys for extreme conditions.

- Micro-Molding Capabilities: Achieving high precision in miniature components critical for medical and electronic applications.

- Automation and Robotics: Increasing production efficiency and repeatability through automation.

- Eco-Friendly Manufacturing: Implementing sustainable practices to reduce waste and energy consumption.

Comprehensive Support for Your Metal Fabrication Projects

At DeepMould.net, our customer-centric approach ensures that each project benefits from dedicated technical support, detailed project planning, and transparent communication. Our services include:

- Design for Manufacturability (DfM): Assisting clients in optimizing designs for manufacturability and cost-effectiveness.

- Prototype Development: Rapid prototyping to validate designs before mass production.

- Material Selection Assistance: Recommending suitable alloys based on application requirements.

- Production Scheduling & Logistics: Ensuring timely delivery and efficient supply chain management.

- Post-Processing & Finishing: Providing secondary operations such as machining, coating, and surface treatment to achieve desired specifications.

Your Trusted Partner in Metal Fabrication & Injection Molding Manufacture

Partnering with DeepMould.net means choosing a company committed to excellence, innovation, and customer satisfaction. We understand that the success of your project hinges on precision, quality, and timely delivery, and we dedicate ourselves to exceeding expectations every time.

Conclusion: Why DeepMould.net is the Ultimate Choice for Metal Fabricators Specializing in Injection Molding

In an industry where precision, efficiency, and innovation define success, DeepMould.net stands out as a leader in metal fabrication with a specialized focus on injection molding manufacture. Our comprehensive capabilities, technological advancements, and unwavering commitment to quality ensure that your projects are in expert hands, from concept to completion.

Whether you seek to develop complex miniaturized components or large-scale metal assemblies, our dedicated team is ready to turn your ideas into reality with unmatched skill and precision. Trust us to be your partner in advancing your manufacturing capabilities and achieving your business goals.

Reach out today and discover how our expertise in high-end metal fabrication and injection molding processes can elevate your products and differentiate your business in a competitive marketplace.